Purposes of

Non Destructive Testing

- Ensuring the Integrity and Reliability of the Product

- Preventing Accidents and Saving Lives

- Aiding in Product Design

- Controlling Manufacturing Processes

- Lowering Manufacturing Costs

- Maintaining Uniform Quality Level

No single NDT method is applicable for all flaw detection or measurement needs. Each method comes with its own set of advantages and limitations.

CONTACT US

Radiographic Testing (RT)

Film Radiography

Film and processing chemicals are commonly used in this method.

Apave provides Gamma ray – (Ir-192, Co-60, & Se-75) & X-rays.

Digital Radiography (DR)

Digital radiography significantly reduces radiation doses compared to film applications. New imaging techniques enhance defect visualization and enable more accurate evaluations.

Computed Radiography (CR)

Computed radiography uses flexible, photo-stimulable phosphor (PSP) plates in cassettes, exposed similarly to traditional film radiography. The cassette is scanned with a laser reader, converting the image to digital format for easier archiving and electronic distribution.

Apave provides Computed Radiography with Ir-192, Co-60, Se-75, X-rays (CR can also be performed with SCAR/CPR system).

Small Controlled Area Radiography (SCAR) / Closed Proximity Radiography (CPR)

SCAR systems use special projectors with Selenium 75 sources and controlled beam collimators, along with additional shielding, to reduce radiation levels to safe limits for open field radiography at construction sites. Apave provides SCAR / CPR systems approved by competent authorities for 24/7 use without hindering other construction activities.

Apave provides Small Controlled Area Radiography (SCAR) / Close Proximity System (CPS).

Ultrasonic Testing (UT)

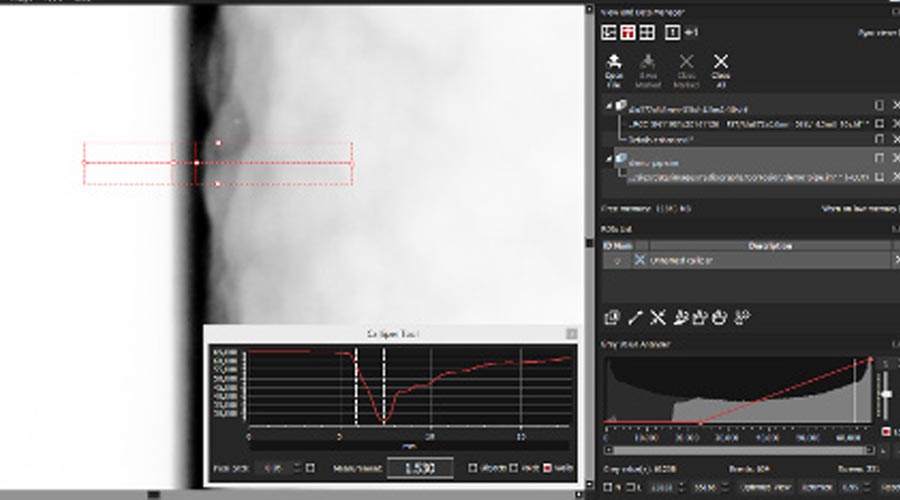

TOFD (Time Of Flight Diffraction)

The TOFD technique offers a computerized and automated approach for weld inspection, capable of scanning, storing, and evaluating indications in terms of height, length, and position with unprecedented accuracy compared to other ultrasonic methods. However, TOFD has two blind zones where it cannot detect defects, necessitating supplementary conventional pulse-echo examinations of the near and far walls.

Phased Array UT

Phased array technology overcomes many inconsistencies found in manual applications. A phased array probe consists of numerous small elements arranged in a line or cluster. By activating these elements with specific voltages, a beam of predetermined angles can be produced. The active elements can be moved to simulate manual techniques. Data collected during the inspection can be imaged as a C-scan, similar to a radiograph, and complemented by A-scan, B-scan, D-scan, and S-scan (sectorial scan) views.

Apave provides:

- Flaw detection on raw materials, plates, forgings, castings.

- Weld test using longitudinal angle, creep & shear wave probes.

- UT – TOFD, PAUT.

- Thickness Measurement.

- Special probes to measure thickness on 10 mm OD tubes.

- Thickness of thin materials min 0.6 mm.

- Through paint thickness on steel measurement possible.

- Thickness measurement on hot surfaces up to 600 C.

- Bond Testing.

- UT ‘A’ scan continuous recording facility.

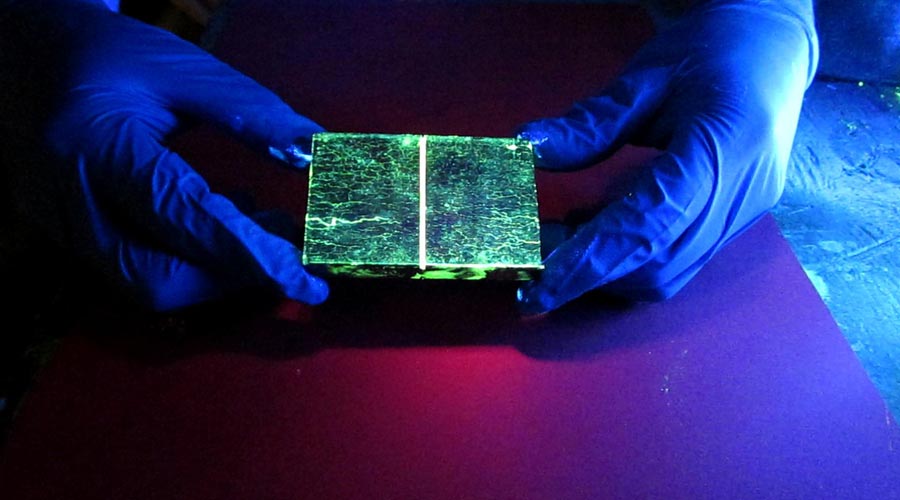

Magnetic Particle Testing - MT (Wet & Dry - Fluorescent & Non Fluorescent)

Magnetic particle testing (MT) detects discontinuities in ferromagnetic materials, such as iron, steel, nickel, cobalt, and their alloys. MT is highly effective at identifying cracks, laps, seams, and similar surface and near-surface discontinuities.

Apave provides:

- Prod type (Up to 8000 Amps – Coils, Central Conductor, Head shots)

- Electro Magnetic yoke

- Permanent Magnet

Liquid Penetrant Testing / Dye Penetrant Testing - PT (Fluorescent & Non Fluorescent)

Leak Tests (LT)

Apave provides:

- Helium leak detection – Mass spectrometer

- Detectable leak rate - Pressure vacuum 10-2 to 10-11 cc/sec.

- Detectable leak rate - Vacuum method 10-4 to 10-10 cc/sec.

- Detectable leak rate - Pressure method 10-1 to 10-7 cc/sec.

- Ultrasonic Leak Detection to detect gross leak from the system

- Detectable leak rate 10-1 to 10-2 cc/sec.

- Vacuum Leak Detection for tank bottom plates etc

- Detectable leak rate 10-1 to 10-3 cc/sec.

- Halogen Leak detection to locate gross leaks

- Detectable leak rate 10-1 to 10-8 cc/sec.

- Pneumatic leak detection to test pressure leaks

Hardness Testing

Hardness refers to a material's ability to resist plastic deformation, typically by penetration, but it can also mean resistance to bending, scratching, abrasion, or cutting. Evaluating the hardness of welding and other materials is crucial for determining their suitability in processes. We use a non-indenting tool that provides highly accurate readings in any position, and we also measure the hardness of non-ferrous and rubber parts.

Apave provides:

- Poldy Hardness Measurement for Metals

- Non indenting type Hardness Measurement for Metals

- Hardness Measurement of Rubber

Ferrite testing

Apave provides Ferrite testing due to its Austenitic & Duplex materials.

Visual Testing (VT)

Most NDT inspections begin with a visual inspection.

Positive Material Identification (PMI)

Other testing

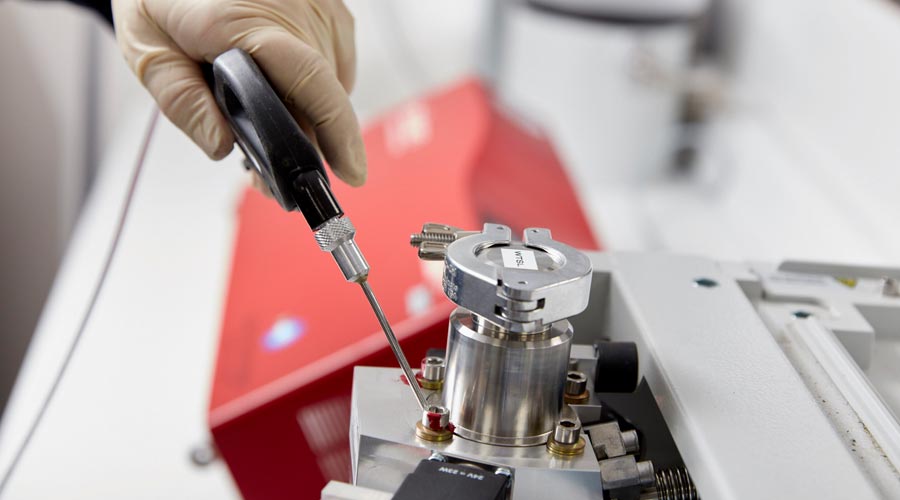

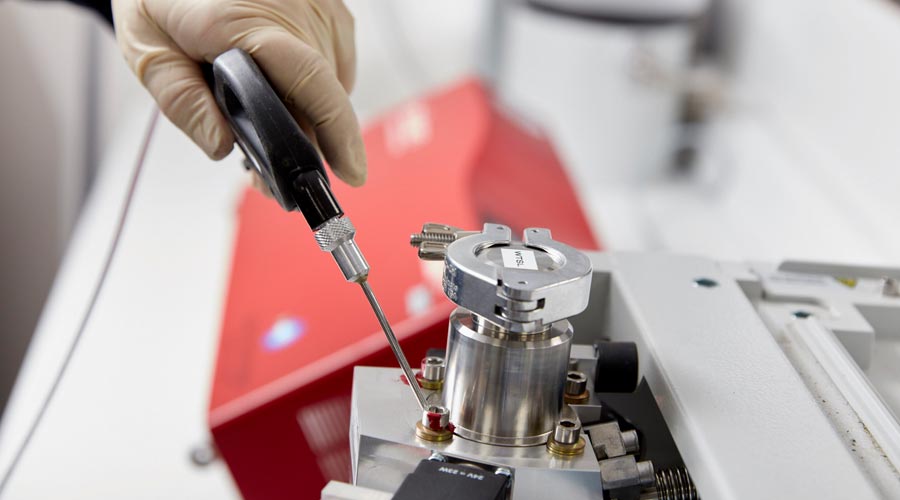

Repair & Servicing of NDT Equipments

Timely servicing and systematic maintenance, including calibrations, are essential for effective NDT operations to complete expected outputs within scheduled timeframes. We also offer preventative maintenance contracts to ensure customer equipment is both calibrated and operating at peak performance.

NDT Training & Consultancy

Success of NDT results is largely depends upon training, qualification & experience of NDT personnel. We train internal & external candidates on various mock-ups for hands on experience in performing NDT and interpretation of results.

We also provide NDT consultancy in establishing system and procedures for NDT.

Our facilities include :

- Reference books in NDT & material processing

- National & International NDT codes & specifications

- Reference Radiographs

- Sufficient Calibration Blocks & Reference Blocks

- Sufficient NDT specimens with covered defects in various configurations for practice

- Radiography Enclosure with darkroom

- Customer specific training

We provide :

- NDT training & Certification to ASNT Level I & II in RT, UT, MT & PT

- ASNT Lv. III services for Inspection & Consultancy in NDT

Our strengths

OUR CUSTOMER RELATIONSHIP APPROACH

OUR EXPERTISE